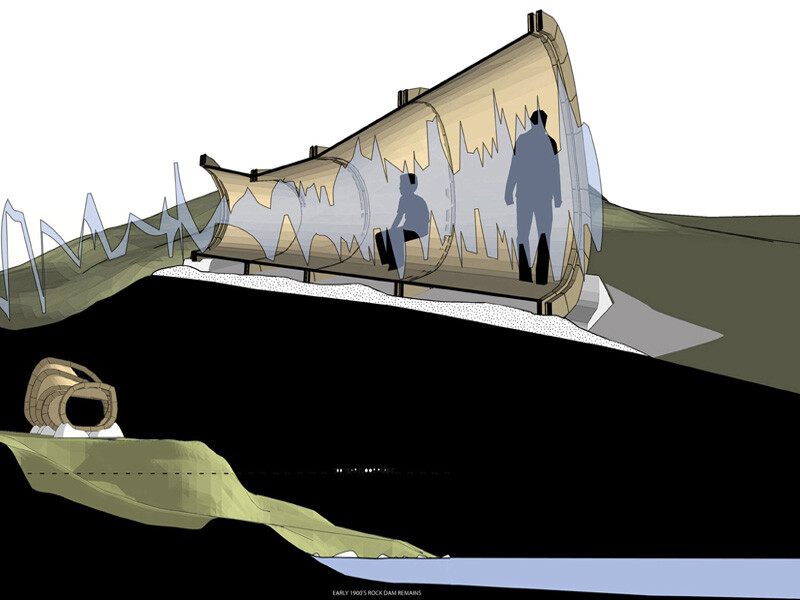

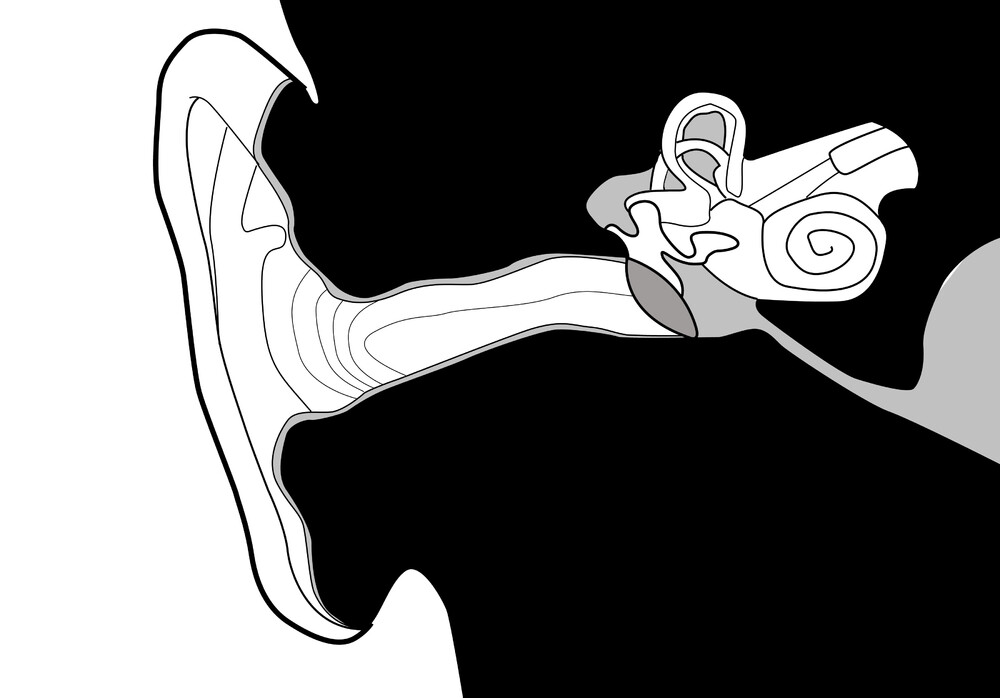

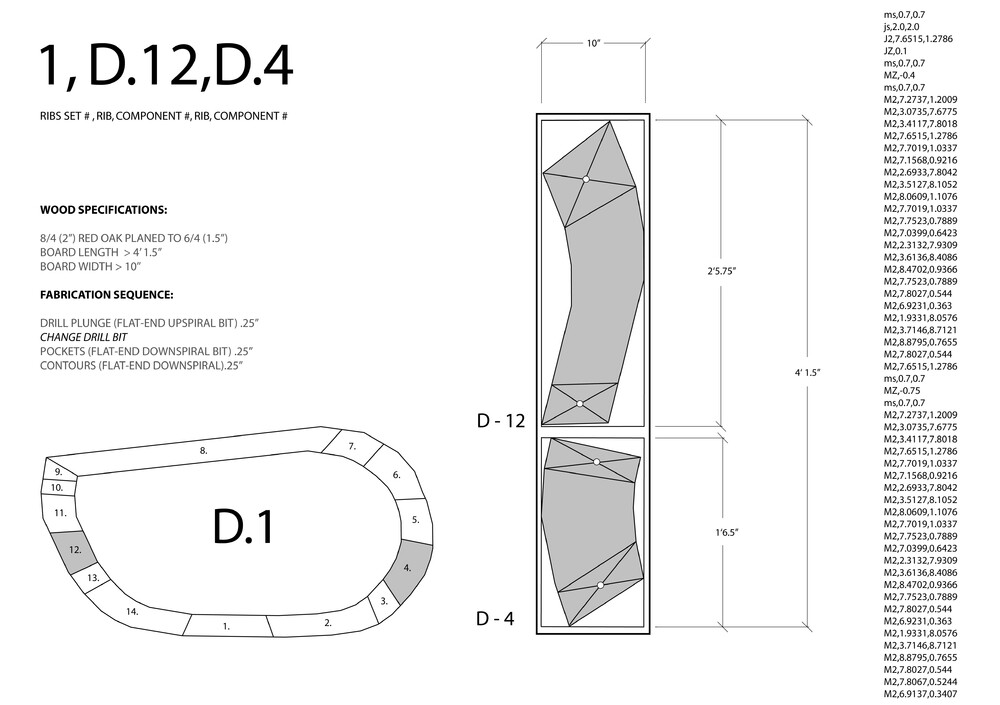

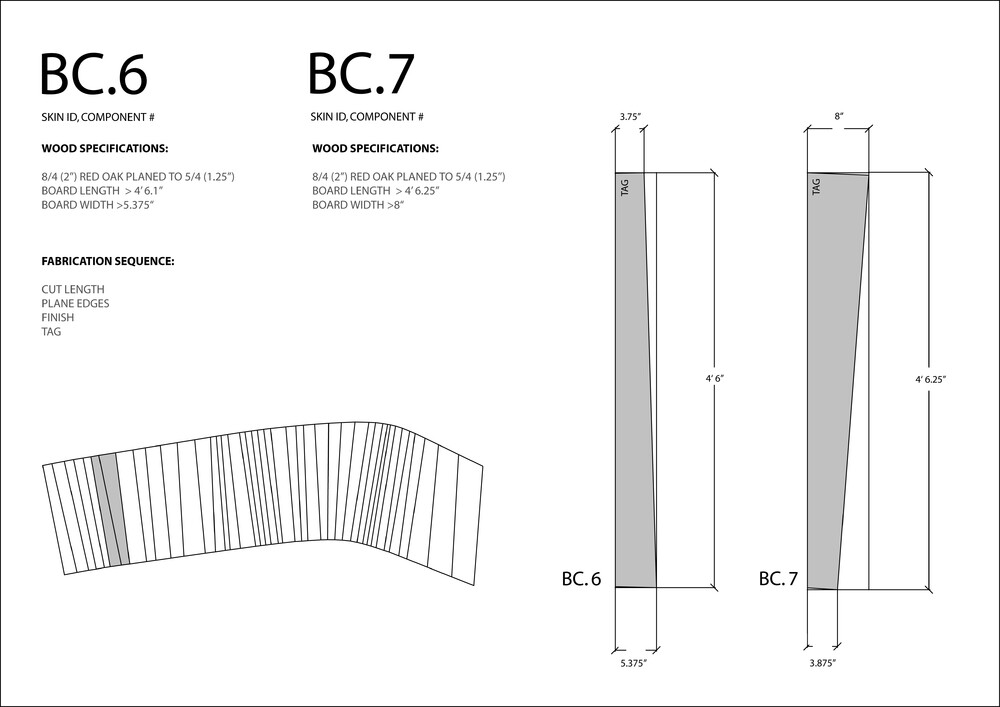

The Calibration Channel is an acoustic shell that amplifies the sound from a river running 30' below. It serves as instrument to promote a heightened awareness of the natural rhythms flowing through the place. The project was modeled after the human ear canal and utilized advanced digital fabrication techniques to achieve a high level of sustainable efficiency. The project was donated to Mounds State Park, in Anderson Indiana. The Calibration Channel was my architectural thesis project during the spring of 2006 _part of Streams-an architectural study focused on utilizing digital technologies to understand/analyze and appreciate the Natural Environment. I was assisted by several undergraduate students during the fabrication and construction phases. The project was made possible by generous donations of material by Indiana manufacturers Indiana Hardwood and Lumberman's Association, Indiana Limestone Fabricators. Project challenges included; processing standard dimensional lumber into irregular/compound shapes, sorting hundreds of components, tagging components as well as an efficient and short installation period on a document Archaeological site. These challenges was overcome via CNC nesting technologies, CNC cutting technologies and digital databases utilized to organize information.

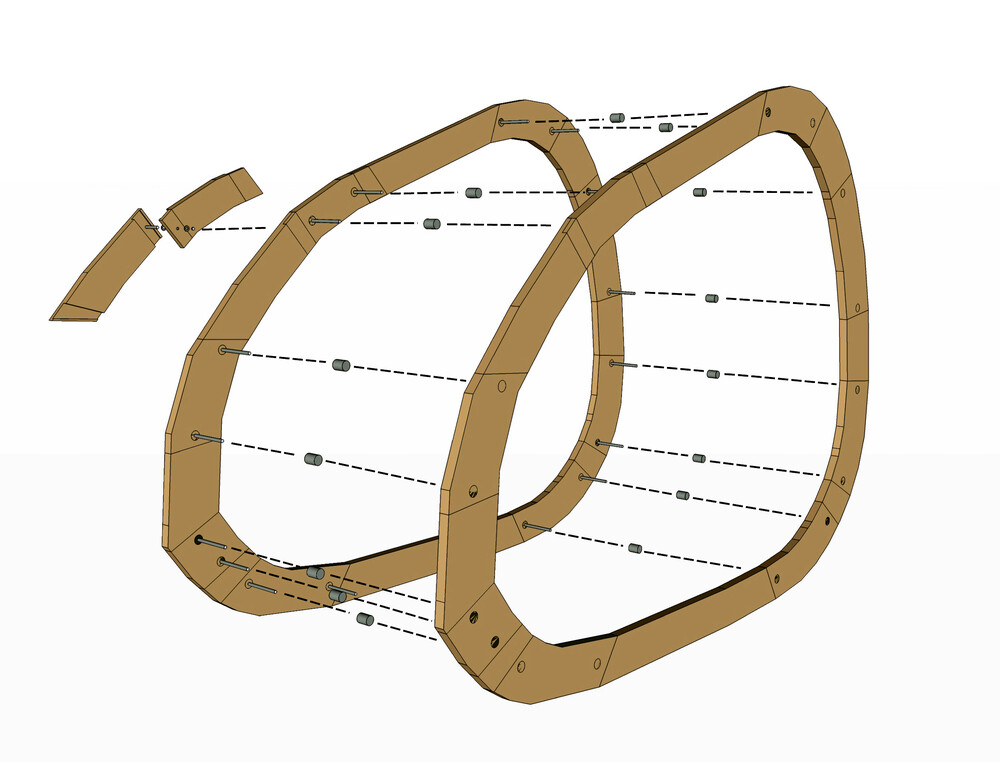

The Calibration Channel pays tribute to the large circular burial mounds of the Adena Culture. The Adena thrived during the 2nd millennium B.C., and utilized the mounds to calibrate themselves to the solstice and equinox. Rooting themselves in the natural rhythms of the sun and the stars enabled the Adena to better know when to plant and harvest. The Calibration Channel aims to root users of the park within the steady shifts of the river, which shifts dramatically over the coarse of an annual cycle. The three structural systems of the Calibration Channel were isolated and fabrication separately. The limestone feet were milled from solid quarried blocks and shipped to site on a flatbed truck. The acoustic shell and structural rib components were nested into donated lumber to maximize the material usage, and were tagged and sorted to be assembled on site. The waste from the entire project fit on a single 8' table. due to the high degree of pre-fabrication, the project was quickly constructed in less than 2 weeks, promoting minimal impact to the project site.

-15.jpg)

-13.jpg)